Efficient storage solutions are the backbone of any organized warehouse or storage facility. Among the diverse range of storage systems available, pallet shelving racks are integral for businesses dealing with inventory management and storage optimization. Understanding pallet shelving racks’ nuances and crucial aspects is vital in maximizing storage space, ensuring safety, and streamlining operations.

This comprehensive guide will delve into five essential facts about pallet shelves, shedding light on crucial considerations that businesses and warehouse managers must know. From understanding the types of racks suitable for specific products to the importance of geographical location in rack selection, this guide aims to provide valuable insights into optimizing industrial storage shelves solution effectively.

What Products Are You Going to Store

The first and foremost consideration when choosing warehouse pallet racks is understanding the nature of the products you intend to store. Different products have varying sizes, shapes, weights, and storage and shelving requirements. For instance, storing bulky items like furniture or machinery requires sturdy and adjustable racks to accommodate varying dimensions. Fragile or perishable goods may require specialized rack systems offering better protection and accessibility. Considering the characteristics of your inventory is crucial in selecting the right type of pallet racks that suit your storage needs.

Types of Pallet Racks

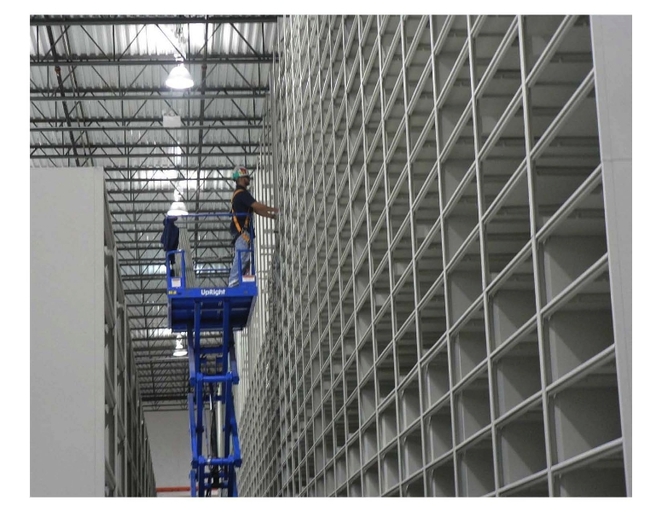

Pallet storage shelves come in various types, each designed for specific purposes. Selective pallet racks, drive-in racks, push-back racks, and pallet flow racks are among the common types available. Selective racks offer accessibility to individual pallets, making them suitable for warehouses with diverse product ranges. Drive-in racks maximize storage space by allowing forklifts to enter and retrieve pallets within the same aisle, which is ideal for bulk storage of similar products. Understanding the functionalities and benefits of each type is essential in making an informed decision aligned with your storage requirements.

Geographical Location

The geographical location of your warehouse or storage facility plays a significant role in selecting and installing industrial storage shelves or pallet rocks. Factors such as seismic activity, climate, and local regulations dictate racks’ design and reinforcement requirements.

For regions prone to seismic activity, racks need to be engineered and installed with seismic bracing to ensure structural integrity and prevent collapse during earthquakes. Similarly, warehouses in humid or corrosive environments may require specialized coatings or materials to protect racks from rust and deterioration.

Rack Decking

Rack decking is a critical component of pallet shelving racks that influences both safety and functionality. It refers to the material or surface upon which the pallets rest within the rack system. Options include wire rack shelves, solid steel decking, and plywood. Wire mesh decking offers improved visibility, airflow, and fire safety, while solid steel decking provides robust support for heavy loads.

Choosing the appropriate decking based on load capacity, product type, and safety considerations is crucial for maintaining a secure and efficient storage environment.

Lifting Loads

Understanding pallet rack shelves’ load capacity and weight limitations is essential for ensuring workplace safety and preventing structural damage. Each type of rack system comes with specified load capacities, considering factors like beam strength, rack height, and shelf material. Adhering to these weight limitations and using appropriate lifting equipment like forklifts or pallet jacks is imperative to prevent overloading, rack failure, and workplace accidents.

Conclusion

Pallet shelving racks are fundamental to efficient warehouse management, offering tailored storage solutions for various products. Understanding the intricacies of product storage, various rack types, geographical considerations, rack decking, and load capacities is essential in making informed decisions when implementing or upgrading storage systems. By considering these crucial factors, businesses can optimize their storage spaces, enhance safety measures, and streamline operations within their warehouse or storage facilities.