Are you looking for ways to improve your warehouse storage system and better manage the inventory in your facility? You’re not alone! Warehouse managers face this challenge, yet many must realize how much impact understanding various warehouse storage systems could have. In this article, we’ll discuss key points to consider when deciding which warehouse storage system is right for you, including the six primary categories of available warehouse storage solutions: rack-style shelving, pallet racks, mezzanines, carousels, and cabinets. We will also explore how each option can help reduce costs or increase productivity within a company’s operations. After reading through our analysis, you should have a firmer grasp of what kind of product might best fit your needs – so let’s begin!

Mobile Shelving

Mobile shelving storage solutions are an excellent way to maximize available space while creating a more organized and structured inventory management system. These systems consist of a series of movable shelving units with fixed aisles that can be accessed by sliding or rolling them along tracks. They are ideal for businesses with limited floor space, requiring less floor space than traditional static shelving options.

The benefits of mobile shelving systems are numerous. They offer increased storage capacity, improve inventory management, and can help to reduce the need for multiple storage units. Most mobile shelving options are designed to be easy to use and maintain, making them ideal for busy warehouses and storage areas. They can also be equipped with safety features, such as locks and brakes, to ensure that stored items remain secure.

Static Shelving

The benefits of mobile shelving systems are numerous. They offer increased storage capacity, improve inventory management, and can help to reduce the need for multiple storage units. Most mobile shelving options are designed to be easy to use and maintain, making them ideal for busy warehouses and storage areas. They can also be equipped with safety features, such as locks and brakes, to ensure that stored items remain secure.

Static Shelving

Static shelving storage solutions are a traditional and reliable method of organizing and storing inventory in a limited warehouse or storage facility space. These shelving units are designed to remain stationary and are ideal for storing items that do not need to be accessed frequently.

Static shelving units are available in a wide variety of sizes and styles, making it easy to find one that suits the needs of any business. They can be made from various materials, especially of recycled steel content, and are typically designed to withstand heavy loads.

The benefits of static shelving systems include their durability, reliability, and ease of use. They provide maximum storage capacity and can be customized to meet specific needs and requirements. Static shelving units are also easy to install and maintain, making them popular for many businesses.

While these storage solutions are effective, they also have some limitations. Static shelving units require significant floor space and are less flexible than mobile shelving options.

Multi-tier Racking

Multi-tier racking is a popular warehouse storage system that maximizes vertical storage space while allowing easy and direct product access. This system consists of a series of mezzanine floors, each designed to support the weight of products and equipment. Stairs, elevators, or conveyor systems provide access to the different levels.

One of the significant benefits of multi-tier racking is the ability to use all available vertical warehouse floor space utilization effectively. Multi-tier racking can double or even triple the facility’s storage capacity for warehouses with limited floor space. Since this type of racking allows products and equipment to be stored on multiple levels, it reduces the number of aisles required, freeing up valuable floor space for other purposes.

Multi-tier racking is also very versatile and is suitable for a wide range of products, from large equipment to small, individual items. Furthermore, it can be customized to meet the specific needs of the warehouse, such as incorporating conveyor systems, lifts, or pallet conveyors to move goods between the different levels of mobile racking.

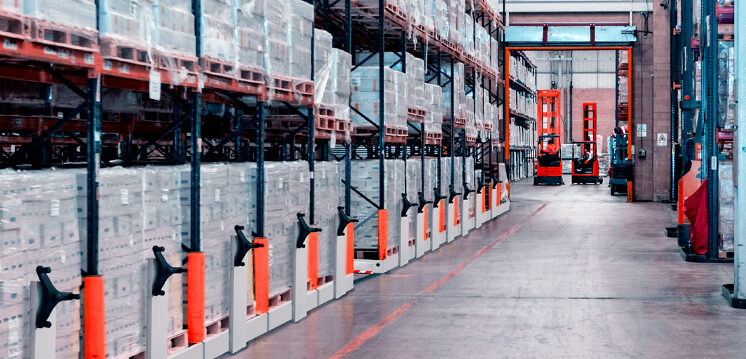

Pallet Racking

Pallet racking is by far the most common type of warehouse storage system in use today. It is designed to hold palletized goods and is ideal for warehouses storing bulk quantities of similar products. Pallet and mobile racking systems are available in several configurations, including selective, drive-in, push-back, and pallet flow racking systems.

Selective pallet racking is the most common type and allows easy access to each pallet. This pallet racking system is ideal for warehouses that require quick and efficient access to a wide range of products. Drive-in racking is another popular option that allows for the efficient use of space by reducing the number of aisles needed. Instead of locating pallets on beams, pallets are stored on rails running from one end of the racking system to the other, allowing maximum storage density.

Push-back and pallet flow racking and pallet flow rack systems provide high-density storage and are ideal for warehouses that efficiently use space and handle large volumes of the same products. Push-back racking allows pallets to be stored up to four deep, while pallet flow racking uses gravity-fed rollers to move pallets toward the picking face. With the right pallet racking system, warehouse operators can maximize storage, improve efficiency, and increase productivity.

Mezzanine Flooring

Mezzanine flooring is an effective warehouse storage solution that can expand the floor space without additional construction. It involves installing a raised platform that takes advantage of vertical space. Mezzanine flooring is an ideal space-saving storage option for warehouses that require extra storage and workspace while preserving ground-level floor space for movement and equipment.

These elevated platforms can support a wide range of storage systems, such as a mobile shelving system and wire storage shelving. Mezzanine flooring can also be customized and designed to meet specific warehouse requirements. Mezzanine flooring is designed with safety in mind. They have safety features, including railings, staircases, and elevators, to ensure easy and secure access to the elevated platforms. Mezzanine flooring is flexible and can be dismantled and relocated if required, making them an excellent long-term investment for warehouse owners.

Wire Partitions

Wire partitions are a warehouse storage system that provides a secure separation between areas. They are made of wire mesh panels that are secured to steel posts and can be customized to fit different configurations. Wire partitions are an ideal storage solution for warehouses that require security and accessibility for storage processes.

Wire partitions come with several benefits, including their durability and flexibility. They can withstand harsh environmental conditions and heavy equipment, making them ideal for industrial and warehouse applications. Wire partitions are also highly customizable and can be designed to suit specific storage requirements.

Wire partitions enhance security by providing a secure barrier between different warehouse areas. They can also secure valuable items and control access to restricted areas and cold storage warehouses. In addition, wire partitions come in different colors and finishes, adding aesthetic value to the warehouse.

Conclusion

As can be seen, various warehouse storage systems out there optimize the productivity and efficiency of any warehouse. When selecting which right warehouse storage system is best for your facility, it is essential to consider the size of your products, the speed with which you need to access them, and the costs associated with each system. By selecting an appropriate system, businesses will see an increase in their bottom line while ensuring they have the most effective warehouse layout possible. Additionally, employees will benefit from an environment that allows them to work better and improves safety protocols. All in all, when selecting the best type of storage system for a warehouse, careful consideration should be taken into account to ensure maximum effectiveness.