Is your warehouse space feeling more like a maze than a well-oiled machine? Pallet racking systems are the backbone of any organized storage facility, but getting the most out of them can feel like a puzzle. Here, we’ll crack the code on maximizing your pallet racking system with tips to unlock hidden storage space, streamline operations, and turn your warehouse into a productivity powerhouse.

Choose the Right Type of Pallet Rack

Choosing suitable pallet mobile storage racking systems is like picking the perfect tool. The wrong one might get things done, but the process could be more efficient. Here’s your toolbox:

- Selective racks: Easy access to individual pallets, ideal for diverse inventory.

- Drive-in racks: High-density storage, like a multi-level parking garage for pallets. Perfect for bulk, similar items, but with limited accessibility.

- Push-back racks: Think dominoes for pallets. Great for high-density storage where you access pallets at the front.

- Pallet flow racks: Imagine a conveyor belt for pallets, ideal for fast-moving similar items.

The key? Match your needs to the rack’s strengths. High product variety and easy access? Selective racks. Tight on space and storing similar bulk items? Drive-in or push-back might be your winners. By understanding your warehouse’s unique needs, you can choose the rack that unlocks the most efficient storage solution. Here’s a complete guide on choosing the right storage system for a warehouse.

Use Both Static and Dynamic Racks

Warehouses aren’t one-size-fits-all, and neither are pallet racks! We’ve got two main categories: static and dynamic. Like the classic selective storage and shelving solutions, static racks are like filing cabinets for your pallets. You can quickly grab any item, which is perfect for warehouses with various products.

Dynamic racks, on the other hand, are all about space efficiency. Think Tetris masters! Drive-in, push-back, and pallet flow racks maximize storage by squeezing in more pallets, but you might need some extra planning to access specific ones. These shine in warehouses with high volumes of similar items – imagine using push-back racks for mountains of bottled water, where you only need the ones at the front most of the time.

The real magic happens when you combine static and dynamic racks. Picture this: selective racks lining the aisles for frequently accessed goods, while push-back racks in the back hold bulk inventory. This way, you get the best of both worlds: easy access to what you need often and maximized space for the rest! Understanding the five must-know facts about pallet shelving racks can help you create better storage solutions.

Start with Longer Rows

Do you ever feel like your warehouse aisles are an endless maze? Here’s a trick: think long, not wide! Fewer aisles with longer rack rows can seriously boost your business storage solutions. Imagine rows stretching like train cars compared to a bunch of chopped-up sections. It’s like gaining extra square footage without needing to expand your walls!

Now, longer is only sometimes smoother. Forklifts have to navigate, too, so stay moderate. The key is finding the sweet spot. Strategically placed wider aisles or specialized narrow-aisle forklifts can keep things moving smoothly, even with those extended rows. It’s all about finding the perfect balance between maximizing space and keeping your warehouse a well-oiled machine.

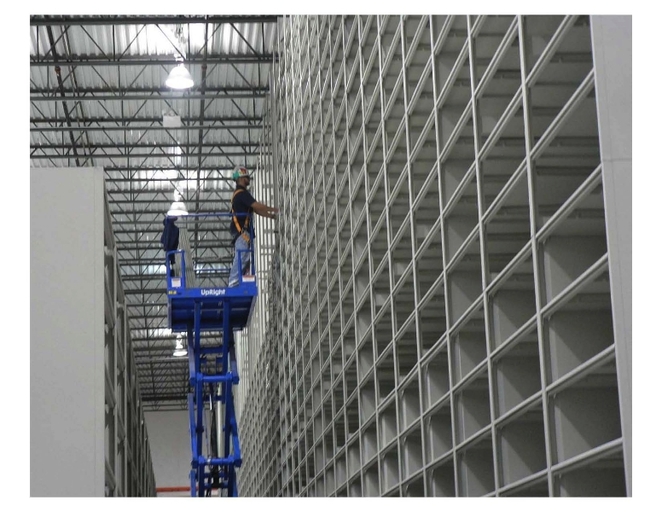

Consider Vertical Space

Warehouses are all about going up, up, and away. Investing in high-quality warehouse pallet racks creates more storage levels and more room for your inventory. Think of it like adding extra floors to your storage building without the construction hassle.

But reaching new heights isn’t just about taller racks. Consider options like mezzanine levels – basically, platforms within your warehouse that create additional storage space. For smaller, frequently accessed items, vertical carousels might be your champion – think of them automated vertical filing cabinets that bring the goods right to you.

Just like stacking blocks, proper weight distribution is crucial. Don’t overload those top shelves – sticking to recommended weight limits keeps your racks sturdy and your warehouse crew safe. So, think tall, but think smart, and your warehouse will become a vertical storage haven!

Optimize Aisle Width

Aisles in a warehouse are like lanes on a highway – you need enough space for smooth traffic flow, but cramming too many lanes in makes navigating a nightmare. Wider aisles mean more storage space gets sacrificed, but super-skinny ones can lead to forklift ballet and potential damage.

To find your golden ratio, consider your forklift crew’s best friends: the size and turning radius of your forklifts. Do they need wide turns, or can they handle tighter corners? Think about your pallet handling needs, too. Do you need space for maneuvering pallets on and off the rack, or is it primarily straight loading and unloading?

Specialized narrow-aisle forklifts can operate in tighter spaces, allowing you to shrink aisle width without sacrificing efficiency. It’s all about understanding your warehouse’s unique needs and finding the aisle width that keeps things moving smoothly and safely.

Implement Proper Load Distribution

Imagine your pallet rack as a weightlifter – it can handle a lot, but only if you distribute the weight evenly. Uneven loading can be a recipe for disaster, compromising the rack’s stability and putting your crew and inventory at risk. Think of a Jenga tower – if you overload one side, the whole thing comes crashing down!

Proper load distribution is critical to keep your racks happy and your warehouse safe. Follow the recommended weight limits for your specific racks and ensure the weight on each pallet is evenly balanced. Picture Tetris again, but this time with boxes – try to distribute the weight uniformly across the pallet base. By following these simple tips, you’ll maximize the lifespan of your racks and keep your warehouse in a safe and efficient zone.

Ensure Proper Usage

Your warehouse crew is the backbone of your operation, and proper training is your superpower when it comes to pallet racks. It is like teaching them the secret handshake to maximize efficiency and safety.

Training should cover the essential moves: safe loading and unloading techniques, understanding weight limitations for racks and forklifts, and following proper operation procedures. Mastering these areas is like learning a new dance – once they’ve got the moves down, your warehouse will run like a well-oiled machine.

The benefits of proper training are a triple threat: improved safety for your crew, reduced risk of damage to your valuable racks and products, and a boost in overall warehouse efficiency.

Optimize Warehouse Space for Efficiency

Imagine your warehouse as a well-oiled machine – products flowing smoothly from one zone to the next. That’s the magic of optimizing your space for efficiency! Strategic placement is vital. Think about frequently accessed items – put them closer to picking zones for a faster grab-and-go. Likewise, you can tuck away bulkier items in less-trafficked areas. Planning your layout with product movement in mind creates a warehouse that hums efficiently, saving you time and effort in the long run.

Conclusion

By following these tips, you can transform your warehouse from a storage maze into a space that maximizes efficiency and productivity. Understand your unique needs and choose the right strategies – from selecting the optimal racking systems to optimizing your layout for smooth product flow. With some planning and these helpful tricks, your warehouse can become a champion of organization and efficiency.