Introduction to Industrial Storage Solutions

Every business faces unique challenges when organizing and storing materials efficiently. Whether you operate a small workshop or a large warehouse, choosing the right storage system is crucial for maintaining productivity and maximizing space. Our beginner’s guide to industrial shelving will give you profound insights into the benefits of industrial high-density mobile shelving. Industrial shelving and racking solutions cater to diverse storage needs, from heavy equipment to delicate inventory items. Options like mobile shelving and modular lockers provide flexibility and scalability, which are essential for dynamic business environments. Understanding these storage systems will help you decide whether industrial shelving or racking suits your operational requirements and space constraints, ensuring you invest in the most influential business storage solutions.

Understanding Industrial Shelving

Definition and Basic Uses

Industrial shelving is a versatile storage solution designed to accommodate a variety of items, from lightweight boxes to moderately heavy machinery. Unlike bulkier storage systems, industrial shelving offers accessibility and flexibility, making it ideal for environments where items are frequently accessed and stock rotation is standard. These systems typically consist of multiple shelves that can be adjusted or reconfigured according to the size of the items stored, making them a perfect fit for retail backrooms, warehouse operations, and parts departments. Shelving systems, such as industrial storage shelves and mobile shelving, help maximize floor space while keeping your inventory organized and readily accessible, enhancing operational efficiency and productivity in any business setting.

Types of Industrial Shelving

Industrial shelving comes in various forms, each designed to meet specific storage and shelving needs and workspace configurations. Here are some of the most common types:

Boltless Shelving: Known for its ease of assembly, boltless shelving snaps together without needing tools, making it a favorite for businesses that value flexibility. Its adjustable shelves can easily accommodate various item sizes, ideal for warehouses or storage rooms that handle varied inventory.

Steel Shelving: When durability is paramount, steel shelving stands out. It can withstand heavy loads, making it suitable for storing industrial equipment or bulky materials. This type is prevalent in manufacturing environments where robust, long-term storage solutions are necessary.

Wire Shelving: This type offers excellent ventilation, making it perfect for storing electronics or any items that require air circulation. The open-wire design also helps keep dust accumulation to a minimum and provides clear visibility of the items stored, which enhances inventory checks.

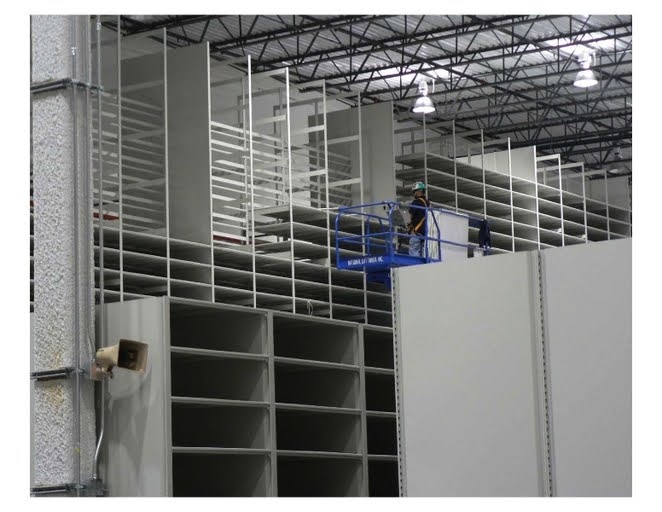

Mobile Shelving: This shelving type maximizes storage efficiency by reducing the needed aisle space. Mobile shelving units are mounted on floor tracks and can be compacted together when access is not required. You can also quickly move them apart when needed. This feature is particularly beneficial in archive rooms or medical supplies areas where space is premium.

You can tailor these shelving options to fit organizational needs, from lightweight goods to heavy industrial components, ensuring your workspace remains orderly and efficient.

Key Differences Between Industrial Racking and Shelving

Accessibility

Industrial racking systems excel in environments where large, palletized goods need quick access, often with the aid of forklifts. This setup is ideal for high-turnover products as it allows for efficient retrieval and storage of bulky items. In contrast, industrial shelving is more suited to manual access, perfect for smaller items that staff can easily handle without mechanical assistance. Shelving often finds its place in settings where products require frequent human touch, such as picking and packing operations in distribution centers.

Weight Capacity

Industrial racking can support substantially heavier loads than shelving, making it ideal for storing bulky materials and large quantities of goods on pallets. Racks can handle thousands of pounds per shelf and accommodate heavy items’ vertical stacking, maximizing warehouse space. On the other hand, industrial shelving typically supports lighter loads and is suitable for hand-stacked goods and smaller items. This difference is crucial for businesses considering their needs for material handling and storage capacity.

Flexibility

Regarding flexibility, industrial shelving offers more versatility in configuration and reconfiguration according to changing storage needs. Shelves can be easily adjusted or reorganized to accommodate different product sizes and shapes. In contrast, industrial racking, while robust, is generally more static. Its configuration can support specific types of goods. It is only adaptable to changes if you make significant alterations, making shelving a better option for businesses that experience frequent changes in the products stored.

Cost

When evaluating cost, industrial shelving generally presents a more budget-friendly option than industrial racking. Shelving units are typically less expensive to purchase and install due to their more straightforward design and the lighter materials required. Conversely, industrial racking systems, especially those designed for heavy loads, involve more substantial materials and complex assembly, which can increase initial costs. However, investing in racking might yield long-term savings for businesses that need to maximize vertical storage space and manage large, heavy inventory efficiently.

Space Utilization

Industrial racking is unparalleled in maximizing vertical space and organizing large volumes of goods in a compact area. Its design prioritizes height and depth to accommodate bulky items stacked on pallets, making it ideal for warehouses looking to optimize floor space. In contrast, industrial shelving is more suited to environments where access and organization at a smaller scale are crucial. It provides excellent visibility and reachability, perfect for retail backrooms, parts departments, and other areas where staff frequently access items.

Conclusion

Choosing between industrial shelving and racking hinges on your business needs—maximizing space, handling heavy loads, or ensuring easy access. Shelving offers flexibility and cost-effectiveness for lighter, frequently accessed items while racking excels in space utilization and supporting substantial weights. Consider your operational demands, budget, and the physical layout of your storage area to make an informed decision. Ensure that whichever system you choose aligns with your business objectives and will enhance efficiency and productivity in your workspace.